UmbrellaScope

Timeline: September – December 2023

Role: Product Designer

Type: Physical Product Prototype

The Challenge

Umbrellas keep us dry in the rain, but once indoors, they become a hassle—dripping water on floors, soaking belongings, and taking up space. This inconvenience led us to develop the UmbrellaScope, a smarter umbrella with a built-in storage container. Our goal: create a quick, compact, and mess-free solution that keeps users dry outside and their belongings dry inside.

The Team & My Role

UmbrellaScope was developed as a collaborative project focused on improving the user experience of carrying and storing wet umbrellas. I worked alongside a teammate to design a functional solution, balancing usability, feasibility, and cost.

My role spanned:

Product Design – Concept ideation, user needs analysis, and iterative design refinements.

Business Strategy – Cost analysis, manufacturing considerations, and pricing estimates.

Prototyping – Initial low-fidelity prototypes, CAD modeling, and material exploration for the final concept.

Understanding the Problem

On a rainy day, we noticed classrooms filled with wet umbrellas, dark puddles forming on carpets, and damp backpacks. This highlighted a common problem: there is no efficient way to store and dry an umbrella indoors.

Problem statement:

A wet umbrella is inconvenient for people moving from outdoors to indoors, and drying it efficiently is difficult.

Key challenges:

Umbrellas dry fastest when fully opened, but this takes up space and leaves water on the floor.

Public spaces lack proper storage for drying umbrellas, leading to wet floors and belongings.

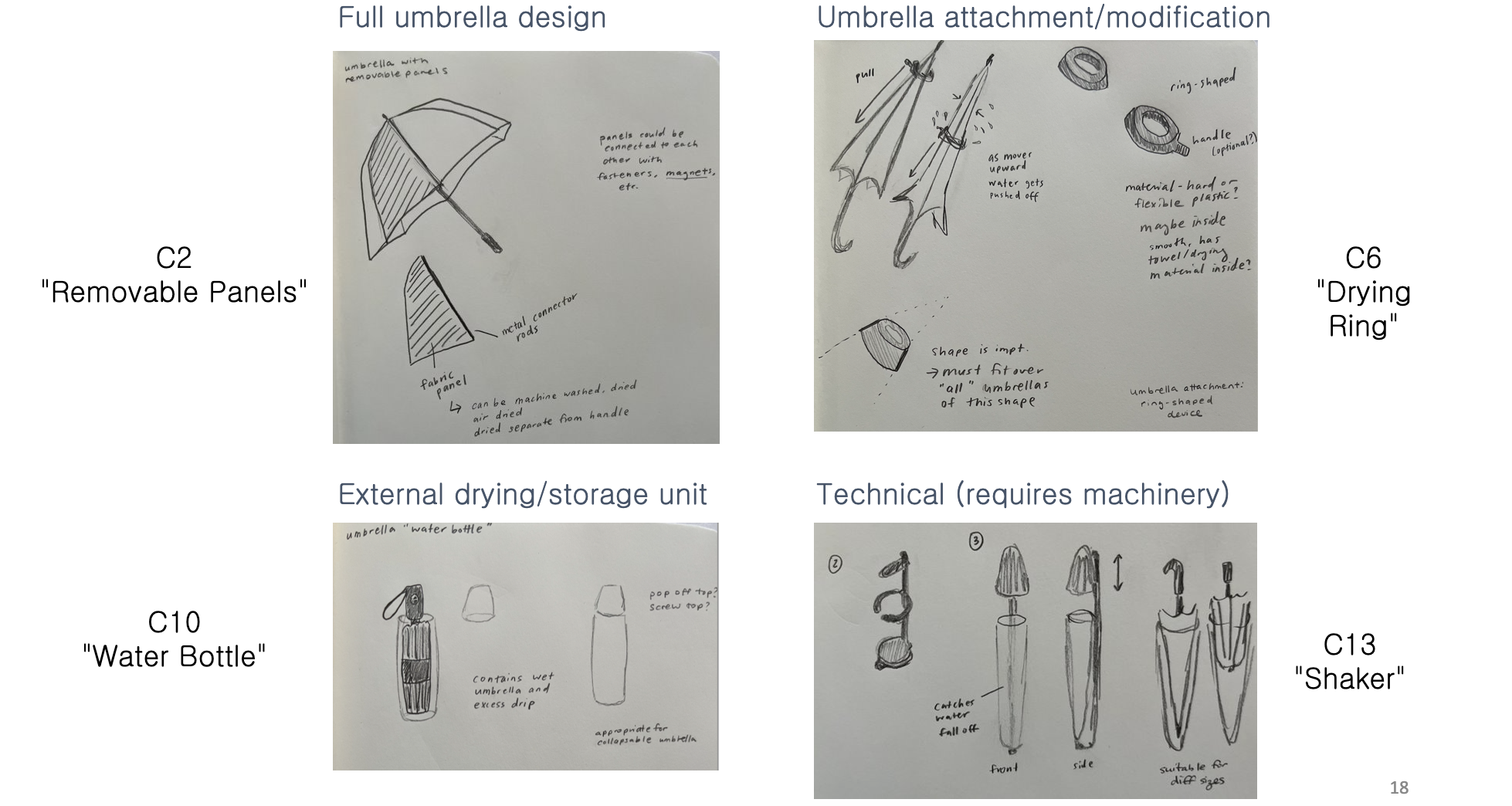

After brainstorming individually, we condensed our similar ideas and came down to 18 unique ideas. We generated critical criteria for comparing the concepts, and then sorted them into 4 categories.

Brainstorming Design Concepts

1. Full Umbrella Redesign

C1 – New Material Wrung Out Umbrella

C2 – Removable Panels Umbrella

C3 – Replaceable Canopy Umbrella

2. External Drying/Storage Units

C8 – Hanging Wall Storage

C9 – External Entry/Exit Container

C10 – "Water Bottle" Container

C11 – Quick Friction Container

C12 – Desiccant Box

4. Technical (Requiring Machinery)

C13 – Shaker Machine

C14 – "Dyson Dryer" Device

C15 – Centrifugal Spinning Device

C16 – Powered Air Tube

C17 – Horizontal "Rotisserie" Device

C18 – Vertical "Shawarma" Device

3. Umbrella Attachments/Modifications

C4 – Fan Attachment

C5 – Panel "Gutters"

C6 – Round Drying Ring

C7 – Drying Brush

Concept Downselection

To refine our ideas, we used a Pugh matrix, comparing each concept against a middle-of-the-road idea: C1 – New Material Wrung Out Umbrella. This process led us to six final concepts:

C2 – Removable Panels

C4 – Fan on Umbrella

C6 – Drying Ring

C7 – Drying Brush

C19 – Solar Oven

C23 – "BottleScope"

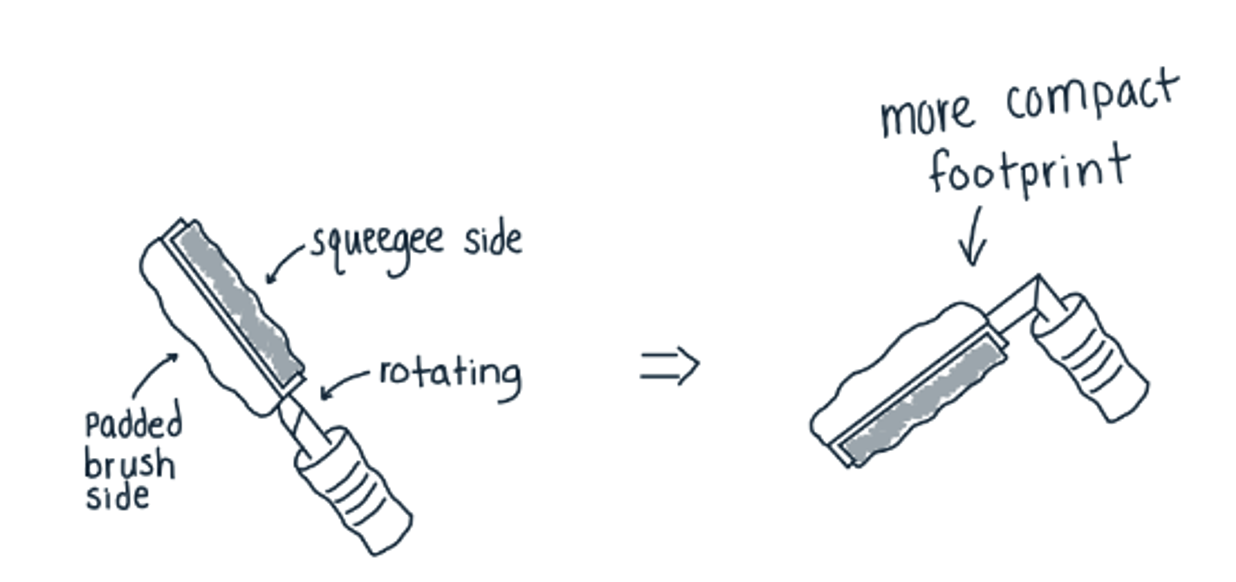

Further downselection using weighted criteria led us to three finalists: Drying Ring, Drying Brush, and BottleScope.Further downselection using weighted criteria led us to three finalists: Drying Ring, Drying Brush, and BottleScope.

C6: Drying Ring — Flexible ring slides down umbrella and squeegees water off

C7: Drying Brush — Flexible brush to manually wipe off umbrella.

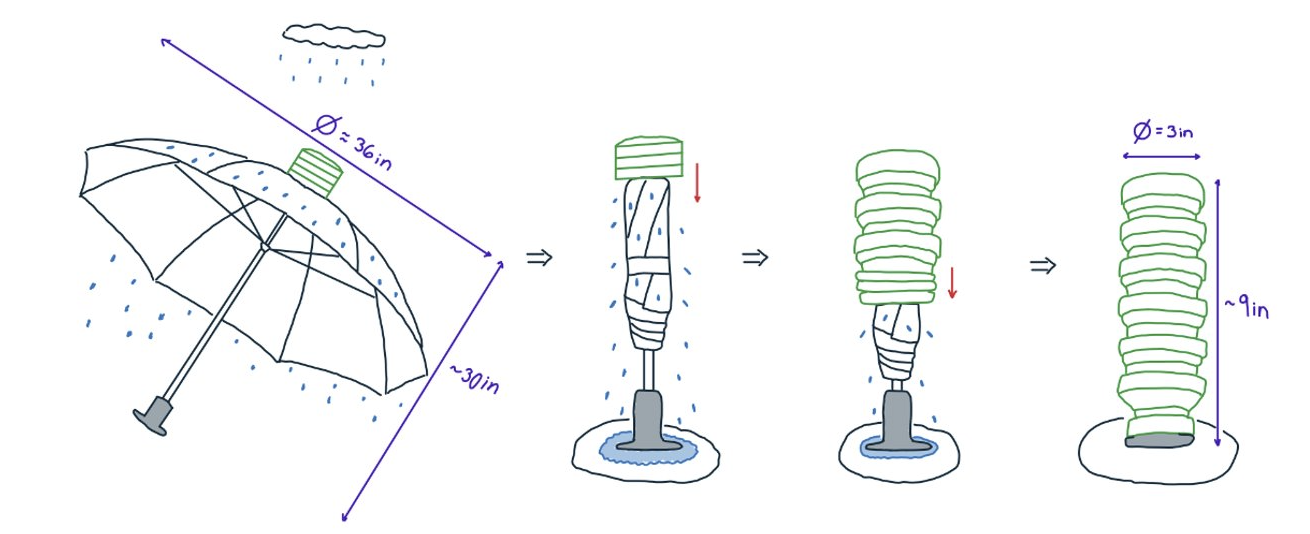

C23: BottleScope — Umbrella with telescoping storage

User Testing & Insights

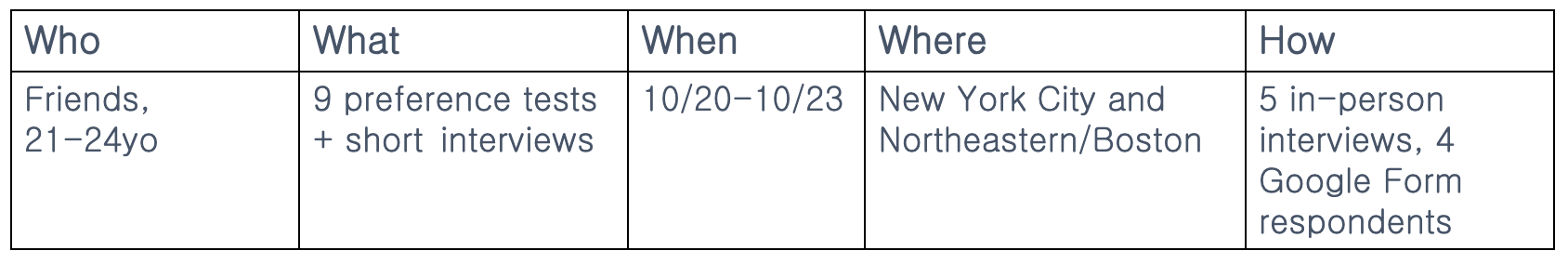

To gain deeper insights, we conducted a preference test with six interview questions.

Key findings:

The bottle storage was the most convenient and portable since it was attached to the umbrella. Users saw it as a “quick fix” for stashing wet umbrellas.

The drying ring was intuitive but could be messy if not used carefully.

The drying brush was the least preferred, requiring extra effort to use.

Likelihood of Use Rankings (1-5):

Brush: 1

Ring: 3

Bottle: 4.5

Given these results, we selected the BottleScope as our final concept.

Prototyping & Development

For our low-fidelity prototype, we experimented with:

Collapsible silicone water bottles for a foldable container.

Silicone swim caps for a flexible, squishable storage method.

Paper cup telescoping models to test expansion mechanisms.

Our V2 prototype was built using an umbrella, an aluminum expandable cylinder, cardboard, and tape, helping us refine mounting and telescoping orientation:

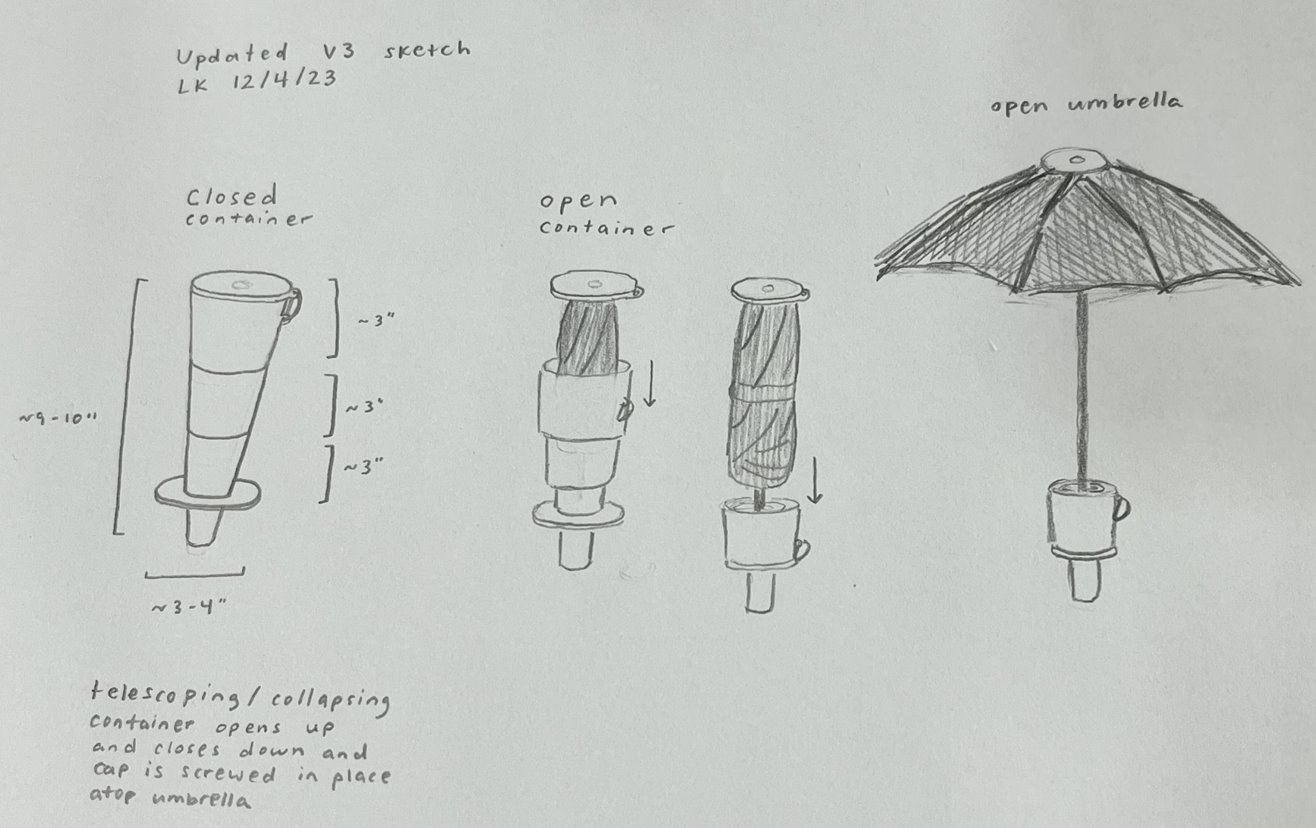

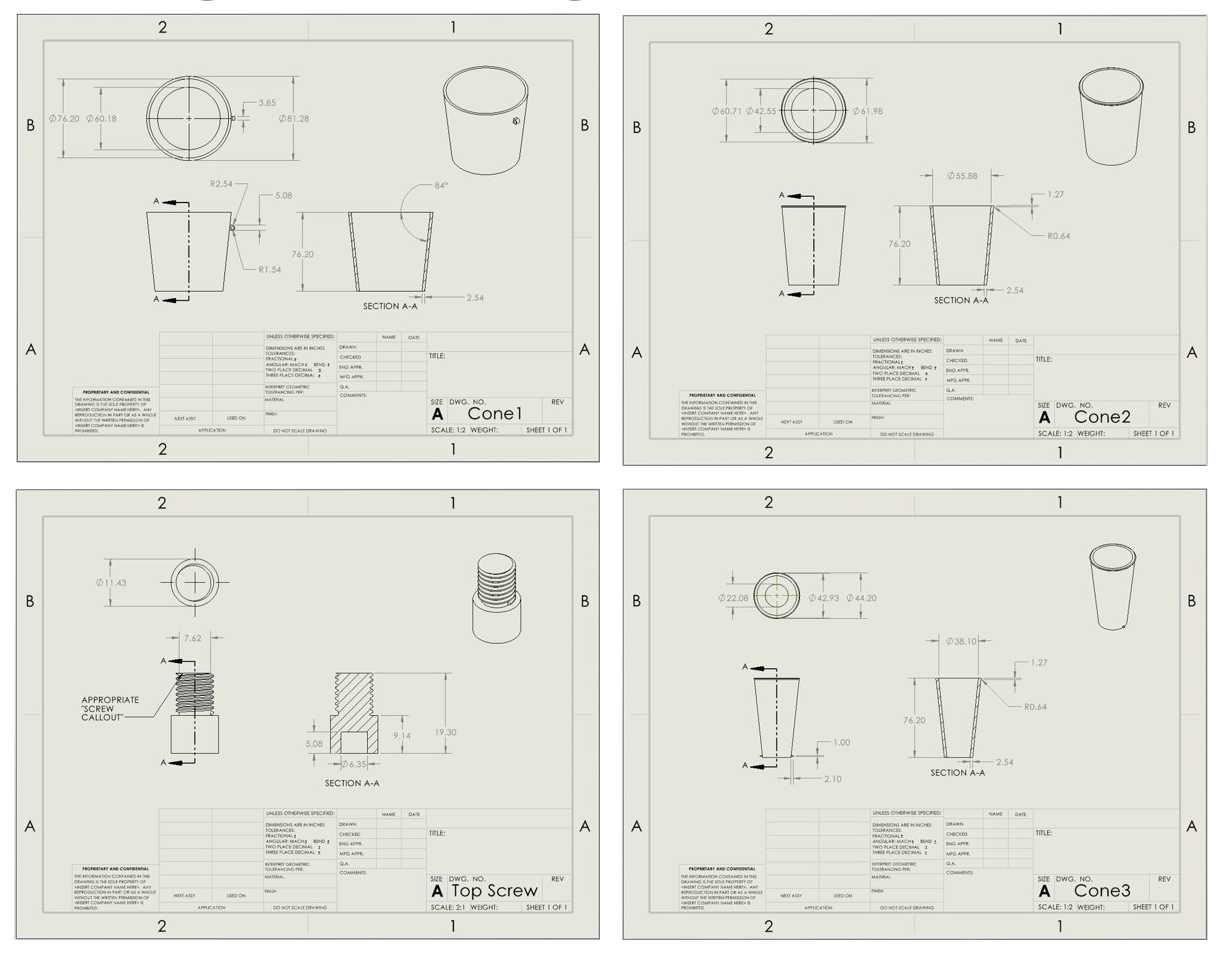

Sketches and Engineering Drawings

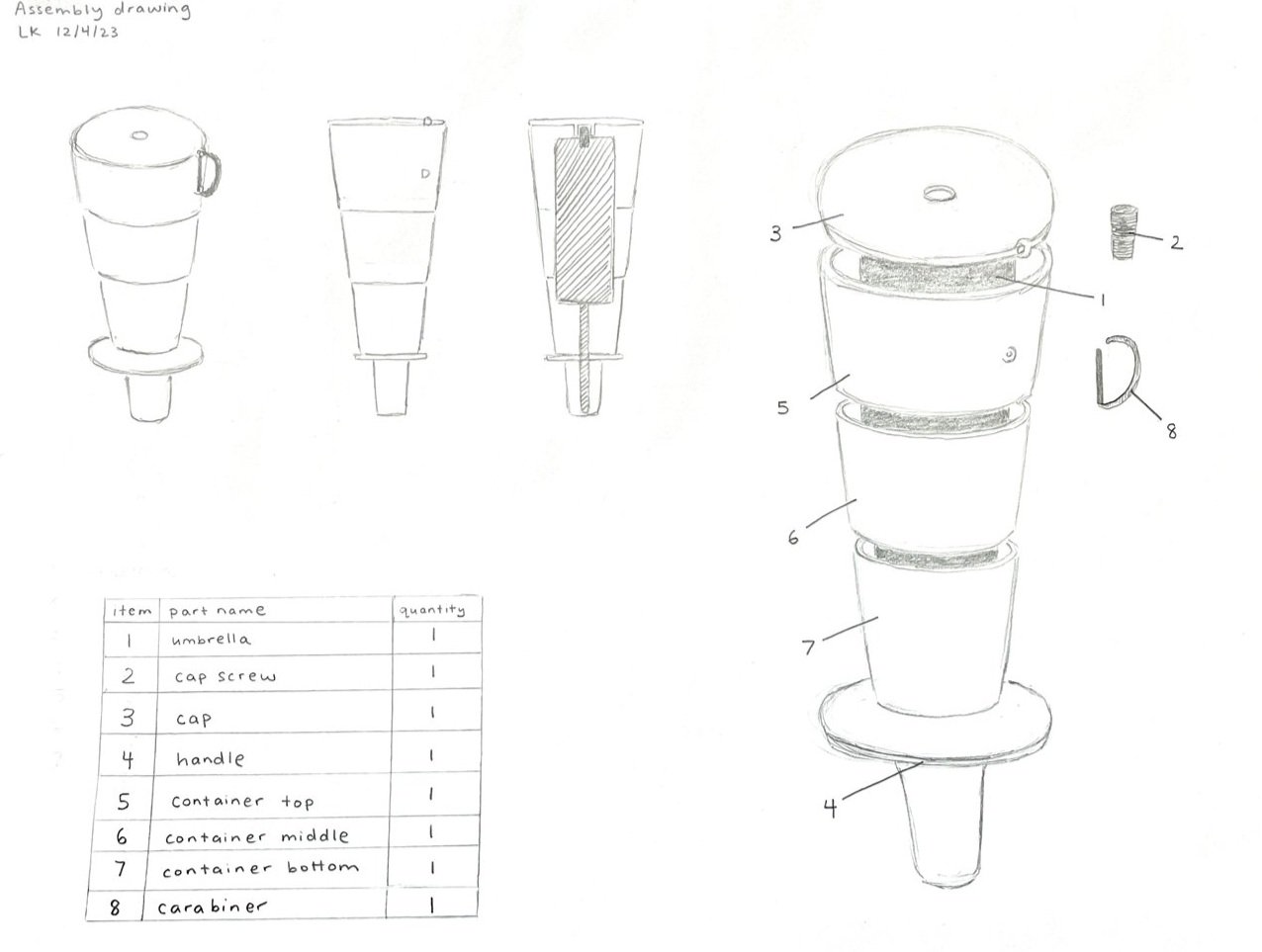

Assembly Drawing

Isometric and orthographic views of the V3 model show the 8 parts:

Umbrella

Cap screw

Cap

Handle

Container top

Container middle

Container bottom

Carabiner

Bill of Materials and Pricing

Cost & Manufacturing Considerations

A standard umbrella (~$3-6 from suppliers)

Injection molding for container components

Estimated cost: $11.53 per unit

Projected retail price: ~$46 (higher than expected)

Final Product and Next Steps

After 13 weeks, my teammate and I had a workable 3D printed prototype of our UmbrellaScope. It was much bigger than expected, as we had to account for error and workability for our 3D print. After presenting our findings to the class, we reflected on our process and experience

If we had a few more weeks, we would...

Work on the size: scale dimensions down, make more streamline and seamless to umbrella shape/size because it is not as small and compact as we intended

Implement drainage system in cap (twist-hole cap, like seasoning shakers)

Work together in person more to stay consistent with design and ideas (ex. we both had slightly differing visual ideas of model V3 when we compared individual sketches)

Conduct usability testing with V3

Work out costs more, try to bring total RTP down

The UmbrellaScope offers a compact, efficient, and user-friendly solution to an everyday problem. With further refinements, it has the potential to be a game-changing product for rainy-day commuters.